Testing Procedure

At Mahamaya Steel Industries Ltd., rigorous testing commences right from receipts of raw material and continues in all the manufacturing steps till the dispatch of the finished products. The Systematic Quality Control Processes ensure the correct chemistry, strength, casting, soundness and dimension standards for all the products are followed to achieve optimal performance.

An Independent laboratory equipped with modern testing facilities for instant annals and hardness testing etc. Supervises and controls various processes and parameters.

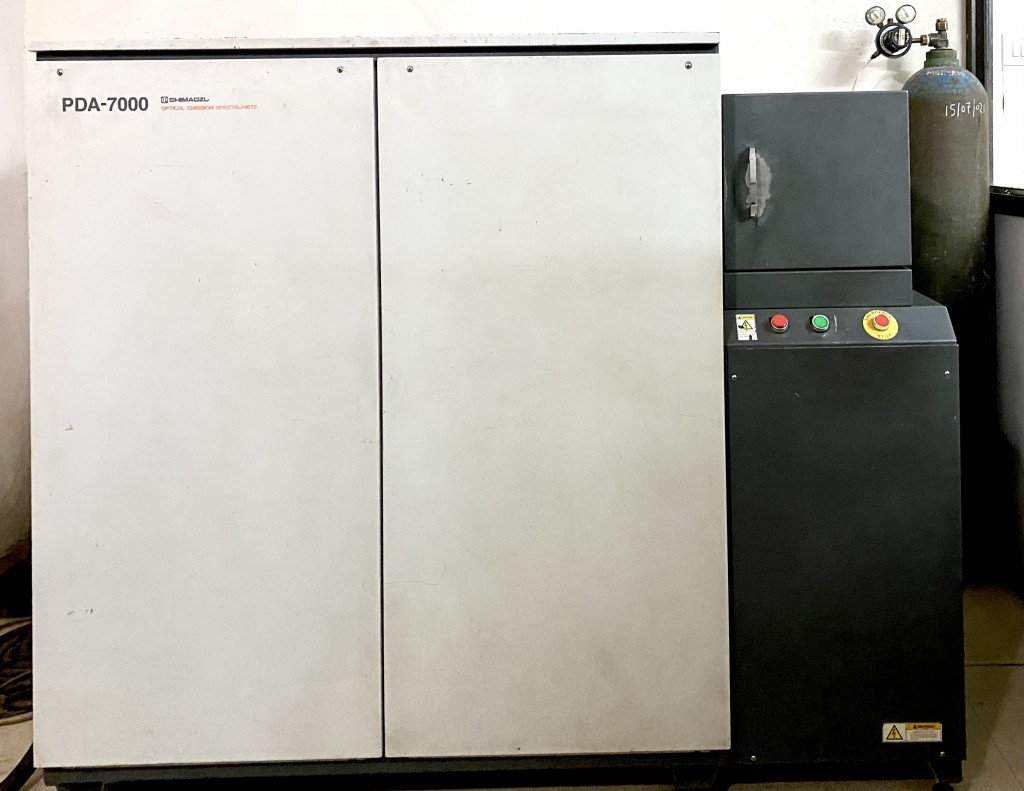

Chemical Testing is performed by Spectrometer to test the various chemical compositions in the products

Mechanical Testing of materials are divided into different parts

- Yield Stress to calculate the elasticity of the steel/ product. By applying maximum stress to it before the shape changes permanently (an approximation).

- Ultimate Tensile Strength (or Tensile Strength) regulates the tensile strength, mechanical performance of the material/ product to resist tearing due to tension.

- Elongation is the increase in the gauge length, measured after fracture of the specimen within the gauge length.

- Band Test deforms the test material at the midpoint causing a concave surface (or a bend) to form without the occurrence of a fracture.; typically executed to determine the ductility or resistance to fracture of that material.

Charpy Impact Test is performed with V notch Sample Preparation Machine that determines the resistance capacity of metal (steel) specimens against sudden impact load of a pendulum, swung from a certain height.

Hardness Test (or Material Hardness Testing) tests the materials’ strength by measuring its resistance to penetration indicating the material can be machined and how effectively it will wear. The test results are extremely useful for material selection.